Grant worth millions for solar panel group at NanoSYD

SDU has received a grant of DKK 5,566,800 from Independent Research Fund Denmark in Technology and Production. The grant will give impetus to research in organic solar panels, so that they can become a serious player in the commercial market. The large amount of money will strengthen the collaboration between SDU and a number of recognized international universities.

Research into organic solar panels reached a milestone last week when researchers from the University of Michigan managed to reach an efficiency of 15%. A clear indication that organic and hybrid solar panels are on the verge of a commercial breakthrough.

Organic and hybrid solar panels have numerous advantages compared with traditional solar panels, which are made of silicon. They are far cheaper to produce and are also extremely thin and flexible, which opens up a range of completely new possibilities. The solar panels can be integrated into windows, and it is even conceivable that due to their flexibility, solar panels could become part of the clothes we wear.

Pleased and proud leader

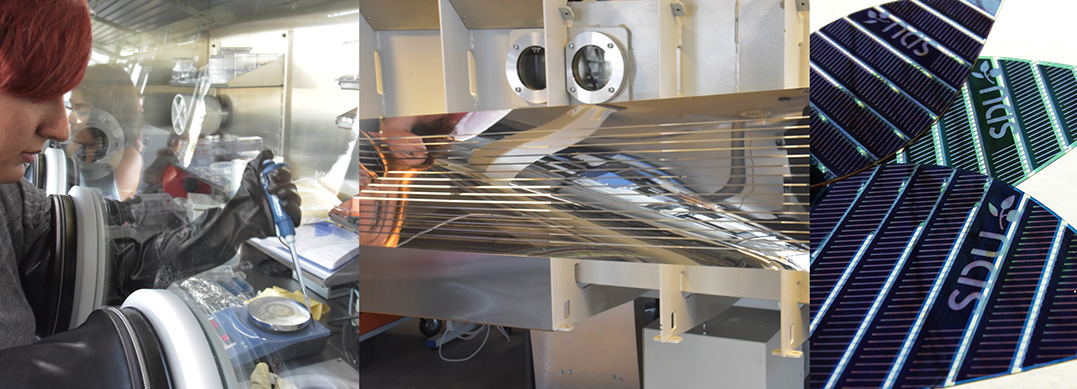

SDU Sønderborg and NanoSYD are at the cutting edge of research in organic and hybrid solar panels, which is also one of the reasons that Independent Research Fund Denmark has awarded them the grant of DKK 5,566,800.

I am proud and pleased that Independent Research Fund Denmark has donated such a large amount to this research project. With this grant we will be able to improve the current state-of-the-art technology in contact coating in a number of different solar panel technologies, which will hopefully benefit the future development of commercial solar panels, says Morten Madsen, leader of the organic solar panel group at SDU NanoSYD.

Boost to both organic and traditional solar panels

The money will be used to develop an ultra-thin coating on organic solar panels. One of the challenges for organic solar panels is that they have a shorter shelf life than traditional solar panels, which are made of silicon. Therefore, the aim is to develop a thin and stable metal oxide contact coating that can be integrated into organic and hybrid solar panels, thereby increasing their longevity. An additional aim is to use the contact coating to improve silicon solar panels, which are far more commonly used at present.

With this project, a new technology will be developed, which could be crucial for advancing the next generation's solar panel technology to a commercial level as well as improving existing commercial solar panels so that they gain a greater foothold on the future energy market.

Specifically, the money will go towards expanding the staff of researchers and purchasing new equipment that will be used to develop the new solar panel coating.

International collaboration

The project will be led by the solar panel group at SDU NanoSYD and has several important collaboration partners, such as Aarhus University, LBL Berkeley, IMEC, UC Berkeley, and UPMC Paris.

The composition of this team for the development and integration of contact coating could not have happened without this grant.

Leader of NanoSYD and the Mads Clausen Institute in Sønderborg, Horst-Günter Rubahn, is just as proud and honoured by the large grant as Morten Madsen, and he emphasizes that the grant should be seen in context with previous, current and future initiatives at the Mads Clausen Institute.

This area of research fits in with SDU's investment in Industry 4.0, where at the Mads Clausen Institute there will be a greater focus on Smart Materials, which covers the development of new, flexible and functional foils as well as devices made of thin film by means of large scale R2R print technology. This will accommodate the material and integration demands of future Industry 4.0 developments, explains Horst-Günter Rubahn.

The Institute Leader draws attention to the fact that these things would not be possible if Danfoss had not three years ago donated an expensive roll-to-roll printing machine, which can be used to produce things like artificial muscles, solar panels, LED and extremely thin, flexible materials, to SDU. The project will run from 1st October 2018 until 31st March 2022.