Capabilities:

Microfluidics lab:

• Pressure-controlled flow system (Elveflow) – with stop flow MUX controller and full programming options• Volume-flow-based systems (syringe drivers) – valves, holders, modular systems

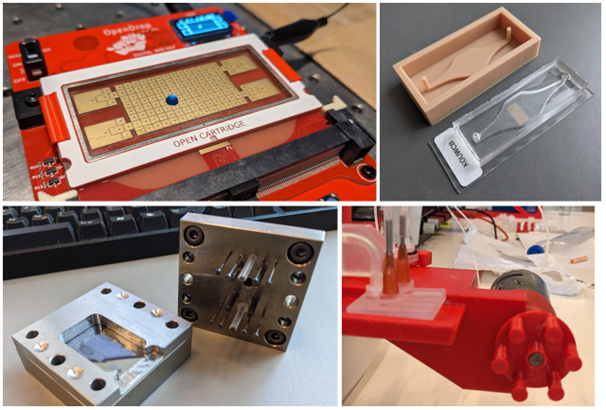

• Digital microfluidics – PCB-based droplet manipulation through computer control, including magnetic

• Sensor integration – Photonic sensors and optical fibres for flow-cytometry in PDMS microfluidic channels

• Optical equipment – lasers, detectors, cuvette spectrometers, optical microscopes

Lab-on-a-chip Fabrication Lab

• 3D printers (Formlabs Form 3B+, Phrozen Sonic Mighty, PRUSA)

• PDMS mixer

• PDMS moulding (3D printed + Silicon masters)

• Bonding/sealing

• PCB digital microfluidics

Exemplary activities and projects

Figure: Various microfluidics systems spanning from PDMS and 3D printed to digital microfluidics

On-chip immunomagnetic separation (IMS) of pathogenic bacteria (PAANEE project)

Modular components are fabricated using state-of-the-art resin-based 3D printers to capture, clean and elute FL-labelled E. coli bacteria.

We also use PDMS microfluidics to integrate optical sensors (CPHNano PCs) for continuous in-flow analysis and investigate in-flow functionalisation for immuno-assays and chemical detection.

Digital microfluidics can also be used for protocol automation, and IMS has already been demonstrated using the OpenDrop platform. 3D printed adaptors also allow integration of DMF with in-flow optical sensors using the pressure-driven Elvelflow system.

Spider silk as model superior biomaterials

Spider silk has extraordinary mechanical properties compared to most manufactured materials. For example, spider silk's tensile strength is comparable to steel alloys; however, it weighs far less and can be spun at room temperature. Due to this unique combination of strength and extensibility, dragline silk has been extensively studied. It is, however, near impossible to obtain spider silk in industrial amounts. Therefore, much research has gone into developing artificial spider silk, which can be spun from an aquamelt in an extremely efficient process. Artificial spider silk would be an environment-friendly and strong substitute for many industrial purposes and environment-friendly processes. Large-scale production of high-quality artificial silk has not been possible, and a full understanding of spider silk from molecule to macroscopic fibre is still lacking. This project aims to design artificial silk with the same or better properties as natural spider silk. To do this, we propose to develop new methods for synthesising artificial spider silk fibres using the acquired knowledge regarding the complex nanostructure of natural silk and a novel microfluidic-based biomimetic fibre spinning technique.